Description

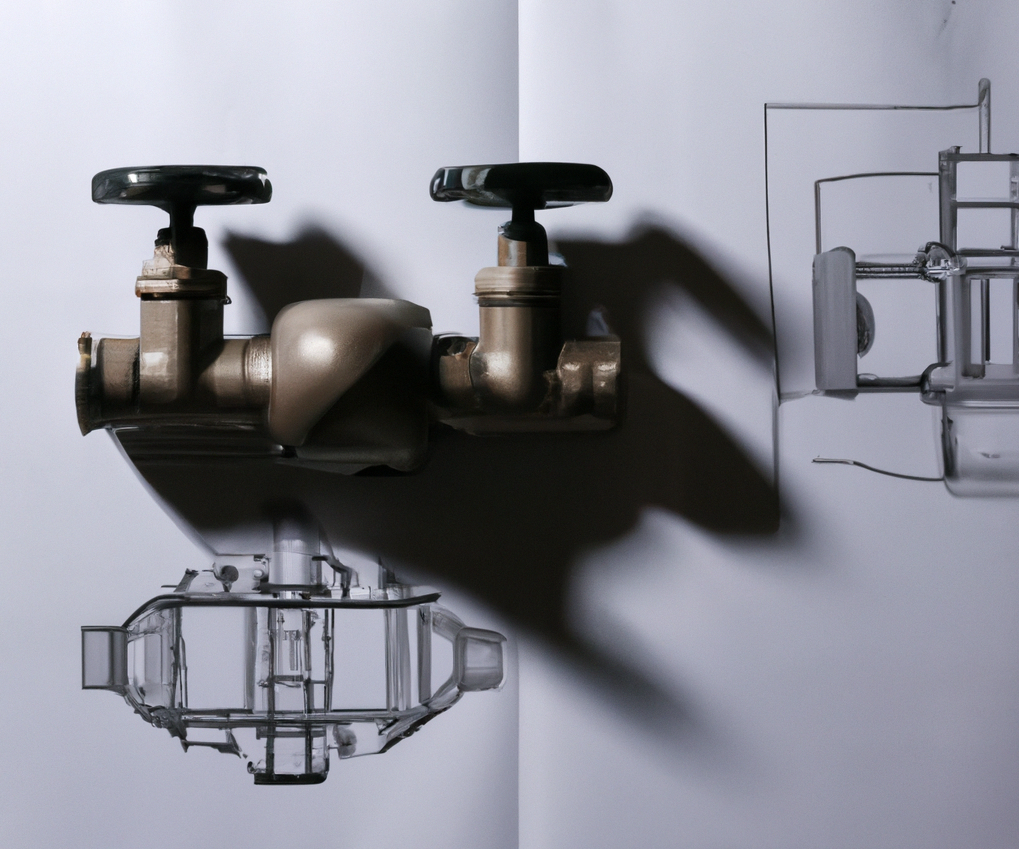

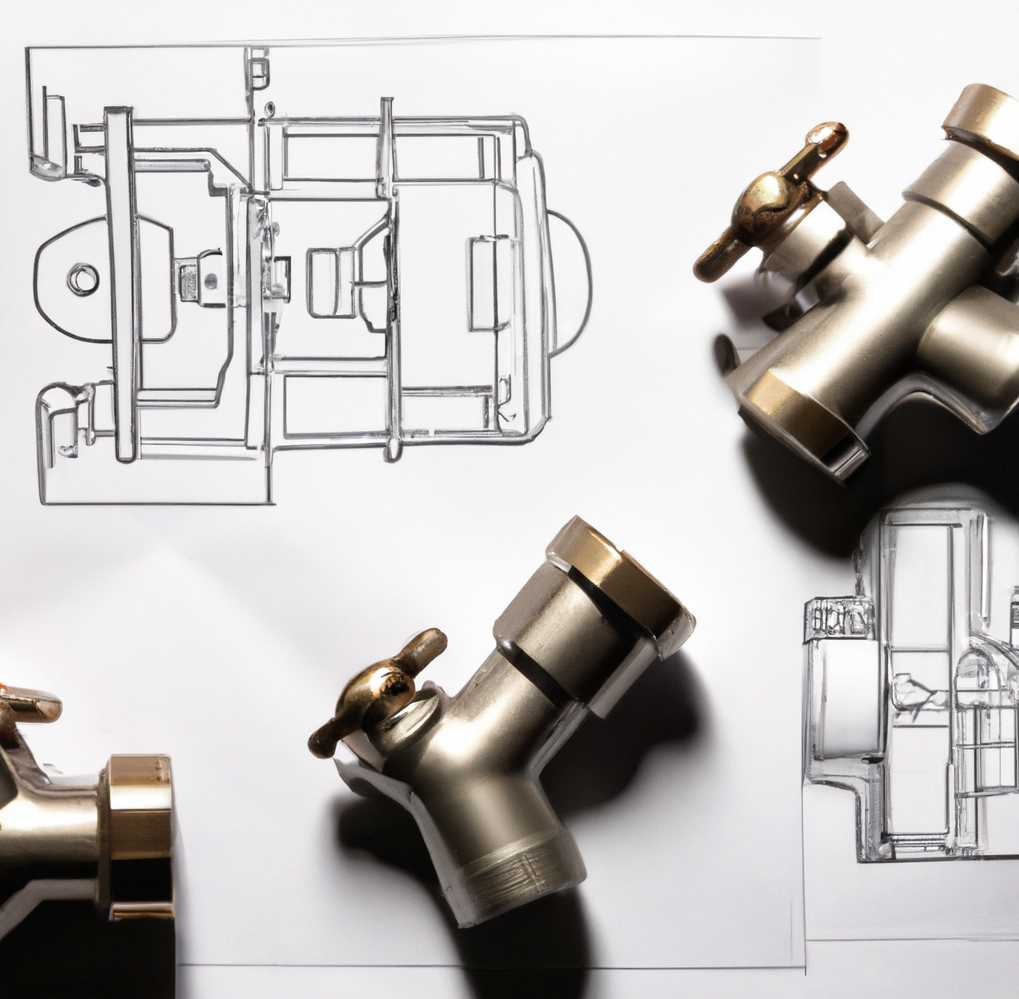

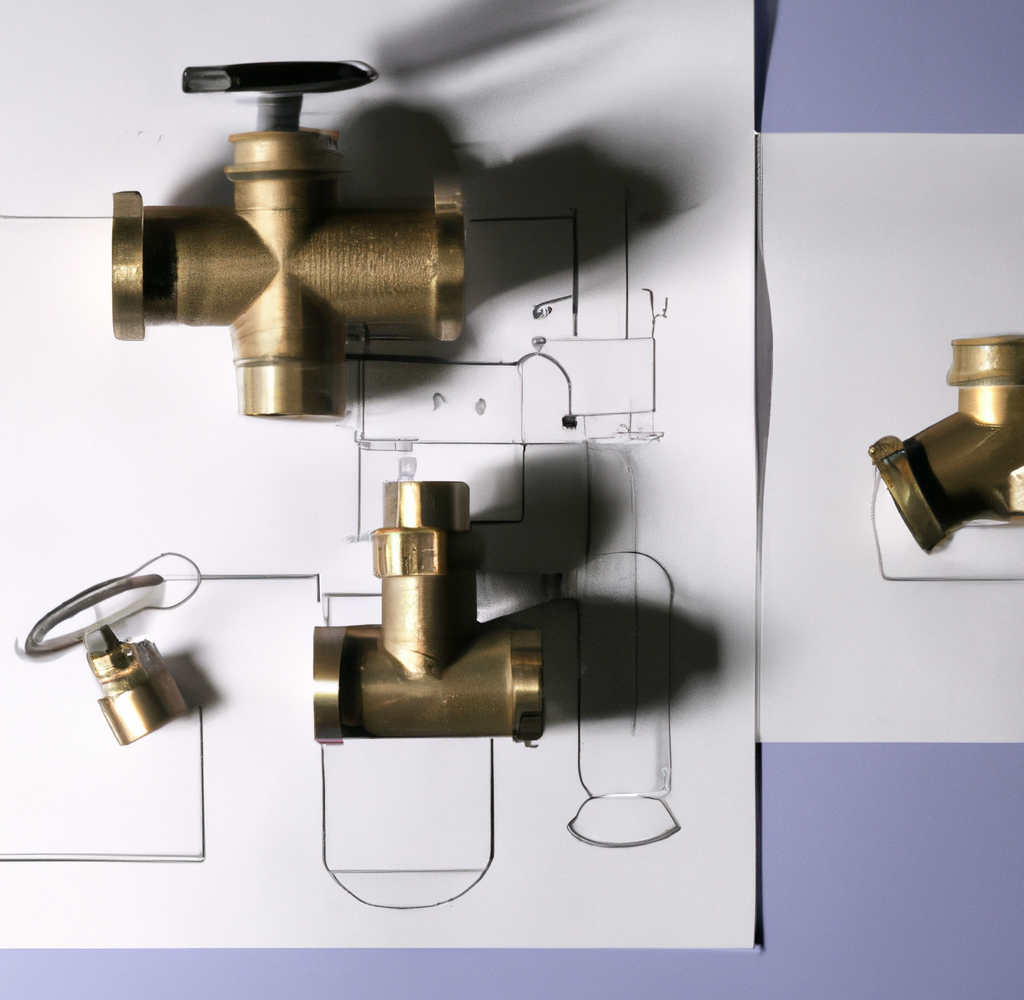

At Sunseal Enterprise, we offer a wide variety of valve solutions, including Ball Valves, Check Valves, Gate Valves, Needle Valves, Butterfly Valves, Globe Valves, Plug Valves, Control Valves, and more. Both low-pressure and high-pressure options are available to suit different industrial applications.

Stainless Steel Ball Valve Malaysia

Our stainless steel ball valves in Malaysia are engineered for durability, corrosion resistance, and precise shut-off control. Suitable for a wide range of industries, they provide long-lasting performance even in demanding environments.

Instrumentation Valve Malaysia

For applications that require precision and reliability, our instrumentation valves in Malaysia are designed to meet strict quality standards. These valves ensure accurate control and safe operation, making them a trusted choice for instrumentation and process systems.

Pressure Regulator Malaysia

To maintain safe and stable system performance, our pressure regulators in Malaysia deliver consistent and reliable pressure control. Built with precision engineering, they are essential for optimizing system efficiency and protecting sensitive equipment.

With Sunseal Enterprise, you’ll find a complete selection of valves and regulators built to meet the diverse needs of the Malaysian market. Explore our range today to enhance the efficiency, safety, and reliability of your operations.

What is the difference between ball valves, butterfly valves, and gate valves?

Ball valves use a spherical ball to provide tight shut-off and are good for quick on/off control. Butterfly valves use a rotating disc and are lighter, more compact, and suited for large diameter pipelines. Gate valves open by lifting a gate out of the flow route: they are better for full open or full close operations but less ideal for throttling.

How to choose the correct size of valve for my system?

Valve sizing depends on flow rate, pressure, pipe diameter, and the type of fluid. It’s important to choose a valve that allows proper control across the full plug opening range, avoids excessive pressure drop, and matches the pipe connection size. Undersized valves can restrict flow; oversized ones may cause instability in control.

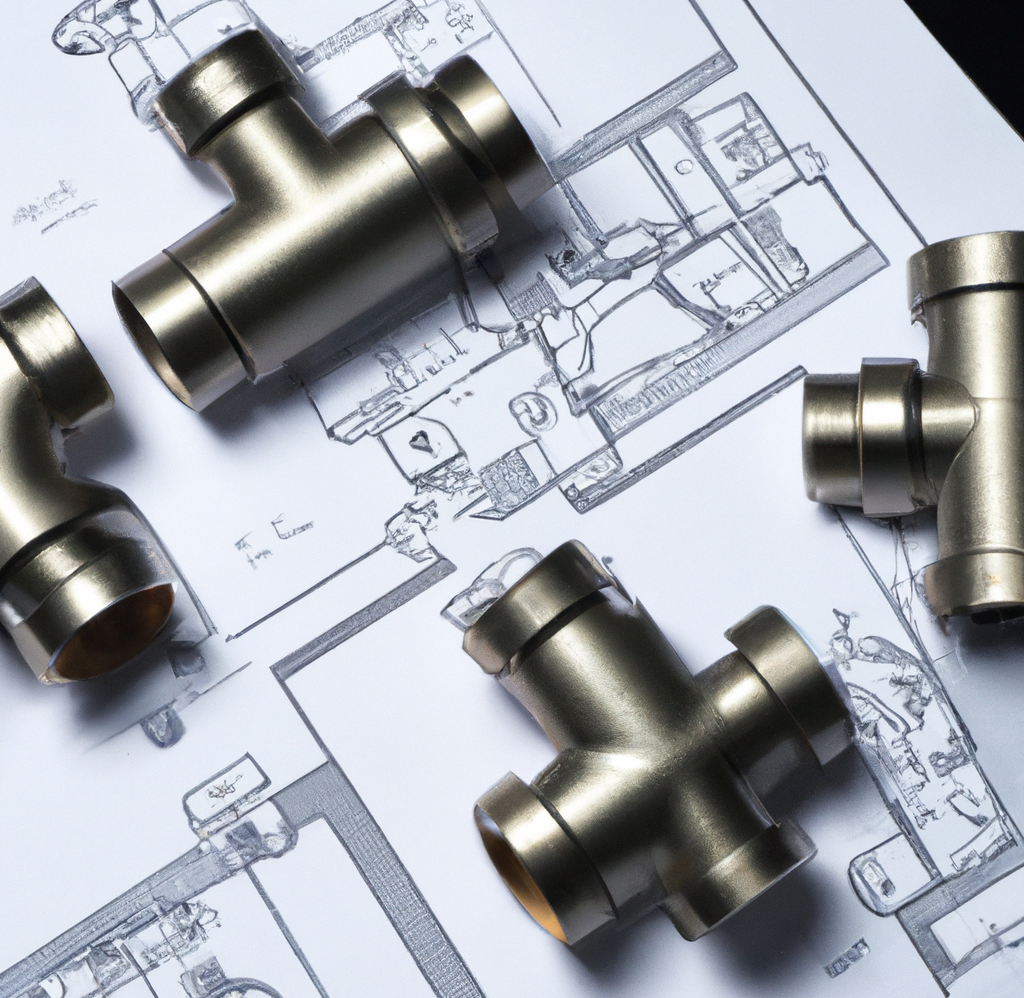

What materials are used for valves and regulators and how do I pick for corrosion resistance?

Common materials include stainless steel, brass, and various alloys. Stainless steel offers good resistance to corrosion, especially in aggressive environments or with chemical fluids. Brass is often used for general service with less aggressive media. Choosing the right material involves considering fluid type, temperature, and exposure to moisture or corrosive agents.

What is a control valve and how does it differ from on/off valves?

A control valve is designed to modulate flow, pressure, or temperature by varying its opening in response to a control signal. Unlike on/off valves (such as ball or gate valves) that are simply open or closed, control valves allow fine adjustments, making them essential in systems requiring precise regulation.

What are common maintenance tasks to ensure valve performance and longevity?

To keep valves working well, regularly inspect for leaks, check valve seats and seals for wear or damage, lubricate moving parts if applicable, ensure the actuator or handle is free-moving, and clean any buildup or debris. Also, service or replace seats or seals when you notice seepage or decline in shut-off performance.