Description

O-Rings:

Universally recognized for their effectiveness, O-Rings are loops of elastomer with a torus-shaped cross-section. When compressed in a groove during assembly, they offer a perfect seal at the interface.

Advantages: Lightweight, flexible, cost-effective, and exceptionally durable.

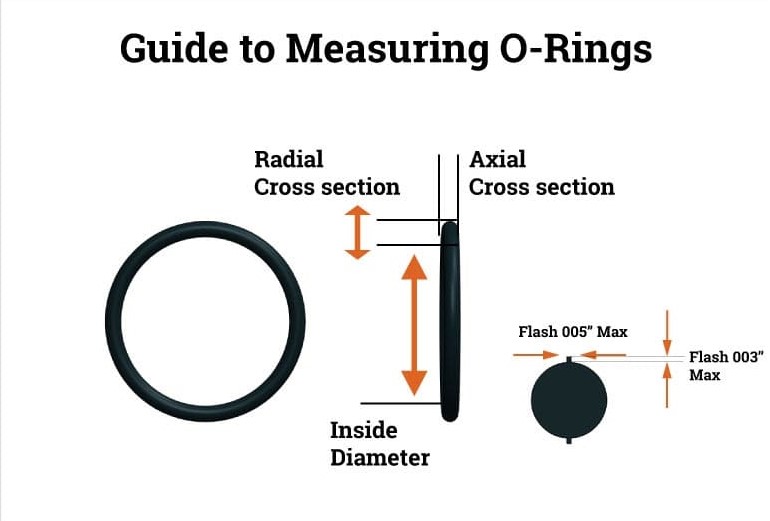

O-Ring Dimensions:

Every O-ring is defined by three dimensions:

- Inside Diameter (ID)

- Outside Diameter (OD)

- Cross Section Width (CS/W)

To understand an O-ring’s size, one typically refers to its ID and CS. For instance, an O-ring size could be represented as ID 20 x CS 2 mm. The OD is derived as: OD = ID + CS*2.

O-Ring Hardness:

Measured in the unit Shore A, the hardness of an O-ring is crucial for its functionality. Generally, a Shore A 70 is ideal, but silicone rubber works best at Shore A 60. The correct hardness ensures durability and resistance against external pressures.

O-Ring Colors:

O-rings in various colors. Recommended standard colors for identification include black for NBR, EPDM, Viton (black and brown), and Red/transparent for Silicone.

O-Ring Cord & Viton Tubing/Hollow Cord:

A testament to our versatility, we also supply high-quality O-Ring Cord and Viton tubing/hollow cord. Whether it’s for custom sealing solutions or specialized applications, these products offer both adaptability and performance.

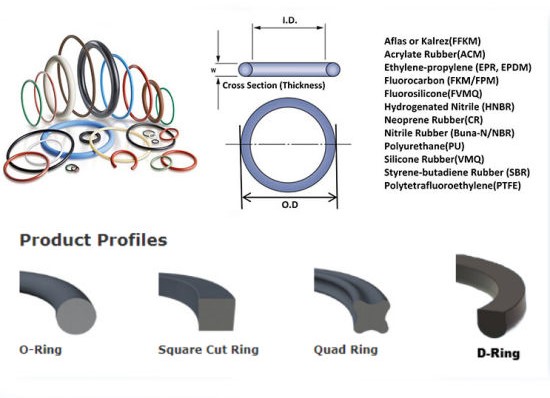

X-Rings:

Known as quad rings, X-Rings come with a double-sealed, four-lipped profile.

Advantages: Reduced friction and increased sealing efficiency.

Square Rings:

With their unique square cross-section, Square Rings offer a broader sealing surface.

Advantages: Enhanced groove stability and spiral twist resistance.

Every product, whether a standard ring or a specialized cord, signifies our dedication to quality and performance.

From sealing air and liquids to ensuring that machinery operates at its peak, Sunseal is the trusted partner for all sealing needs.

Materials:

We offer a plethora of materials, from popular rubber variants like NBR, FKM/Viton, Silicone, Aflas®, and FFKM, to more niche materials tailored for specific applications.

Dimensions:

While our products adhere to international standards such as AS 568B, DIN ISO 3601, and JIS, we specialize in customization, catering to both standard and unique requirements.

Choose Sunseal Enterprise Sdn Bhd for precision, durability, and unmatched expertise in sealing solutions.

V-Rings, also known as axial shaft seals, are flexible rubber seals designed to fit onto rotating or stationary shafts. They create a barrier that prevents the escape of lubricants while shielding against external elements. The V-shape of the ring provides effective sealing even in challenging conditions.

O-Rings are circular elastomer rings with a simple yet efficient design. They are widely used for sealing static and dynamic connections between parts, ensuring a tight and leak-free fit. O-Rings come in various materials, making them versatile for different environments.

Looking for top-quality O-Ring Malaysia and V-Ring Malaysia? You’ve come to the right place! Our extensive inventory features a wide range of seals designed to meet various industrial needs with precision and reliability. Whether you require O-Rings for fluid sealing or V-Rings for rotary shaft applications, we have the perfect solution for you. Our seals are manufactured to the highest standards to ensure durability and optimal performance in diverse operating conditions. Trust us to provide you with O-Rings and V-Rings that effectively prevent leaks and maintain efficient operation. Explore our selection today to find the ideal seals for your specific requirements.

How do Sunseal O-Rings ensure a reliable, leak-free seal in demanding industrial applications?

Sunseal O-Rings are precision-engineered from high-quality elastomers chosen for their specific material properties, such as excellent compression set resistance and resilience. This ensures that when compressed within a gland, they create a tight, uniform seal that prevents fluid or gas leakage under various pressures and temperatures. Our commitment to strict manufacturing tolerances guarantees consistent sealing performance, minimizing downtime and maximizing operational integrity in your critical systems.

What factors should I consider when selecting the optimal O-Ring material for my specific operating environment?

Choosing the right O-Ring material is crucial for long-term performance. Key considerations include the type of media being sealed (e.g., hydraulic fluid, water, chemicals, gases), the operating temperature range, system pressure, and any potential exposure to environmental factors like UV radiation or ozone. Sunseal offers a wide array of materials like NBR, FKM, Silicone, and EPDM, each with unique chemical and physical properties. Consulting our experts can help you match the ideal material to your exact application requirements for superior longevity and reliability.

In what applications do V-Rings offer a distinct advantage over traditional O-Rings, and how do they function?

V-Rings are dynamic seals specifically designed for rotary applications, acting as an excluder seal to prevent contaminants like dust, dirt, and moisture from entering bearing housings, while also retaining lubricants. Unlike O-Rings, which are primarily static seals, V-Rings feature a flexible lip that seals axially against a counterface, rotating with the shaft. This makes them ideal for environments where preventing ingress of external impurities and protecting bearings is paramount, offering excellent low-friction performance and extending equipment lifespan.

How does the quality and manufacturing process of Sunseal O-Rings contribute to reduced maintenance and operational costs?

Sunseal’s rigorous quality control and advanced manufacturing processes ensure that our O-Rings meet stringent industry standards for dimensional accuracy and material consistency. By providing highly reliable seals that resist premature degradation, swelling, or hardening, we significantly extend the service life of your components. This translates directly to fewer seal replacements, reduced labor for maintenance, and prevention of costly leaks or equipment damage, ultimately lowering your total cost of ownership and improving operational efficiency.

Can Sunseal provide O-Rings and V-Rings for both standard and highly specialized or custom sealing requirements?

Yes, Sunseal offers an extensive inventory of O-Rings and V-Rings in standard imperial and metric sizes, covering a vast range of industrial applications. For unique challenges, we also specialize in providing solutions for custom sealing requirements. Whether you need specific materials, non-standard dimensions, or unique profiles to address particular environmental or operational demands, our team is equipped to assist in sourcing or manufacturing the precise sealing solution to ensure optimal performance for your specialized equipment.

What is the main difference between V-Rings and O-Rings?

V-Rings are axial shaft seals suitable for rotary applications, while O-Rings are circular seals used for static and axial connections.

Can I use O-Rings in high-speed rotary applications?

O-Rings are best suited for static or slow dynamic applications. For high-speed rotary use, V-Rings are the better choice.