Description

Our metal tubes and pipes are more than just conduits; they are a blend of metallurgical artistry and advanced engineering. Crafted from high-grade metals, each piece ensures robustness, longevity, and unmatched efficiency. Their resilience against corrosion, pressure, and wear makes them the trusted choice for demanding applications across industries.

Discover the Sunseal promise – where the strength of metal meets the finesse of design, and where every tube and pipe stands as a testament to unparalleled craftsmanship and functionality.

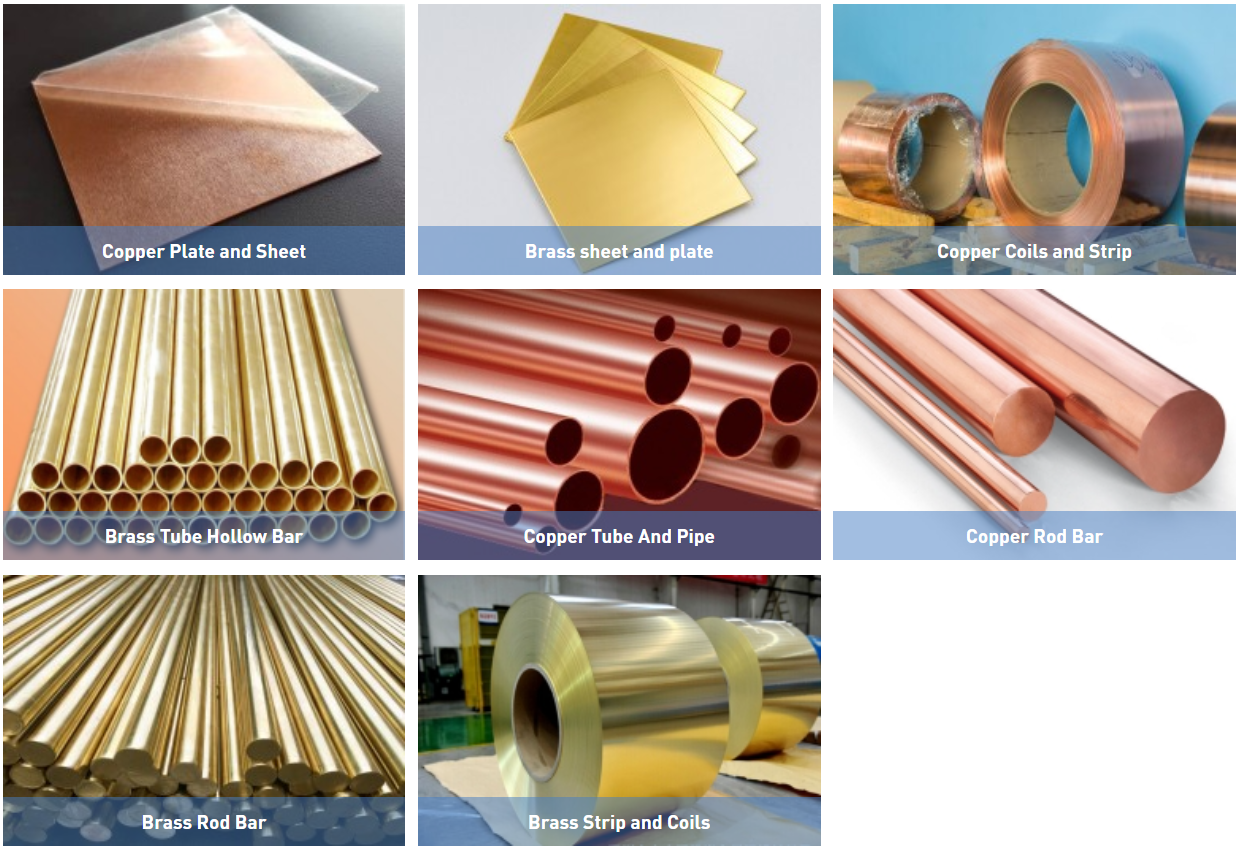

Below are the major SS Tubing that we supplier:

- Stainless Seamless EP (Electropolished) Tube

- Stainless Seamless High-Cleaning BA (Bright Annealed) Tube

- Ultra-High Pressure Tube (HR31603)

- High Purity BPE Stainless Steel Tubing (TP316L, Sulphur: 0.005% – 0.017%)

- Stainless Seamless Instrumentation BA Tube

In addition to metal, we also offer PFA & PP Tubing & Fittings, as well as PC & PVC Pipes.

Discover a comprehensive range of hydraulic fitting Malaysia, designed to meet the demanding requirements of fluid power systems across various industries. Our extensive selection includes a variety of fittings, adapters, couplings, and connectors crafted from high-quality materials such as stainless steel, brass, and carbon steel. Whether you need fittings for hydraulic hoses, pipes, or tubing, we offer a diverse range of sizes, thread types, and configurations to suit your specific application needs. With precision engineering and reliable performance, hydraulic fitting Malaysia ensure secure connections, leak-free operation, and optimal hydraulic system functionality. Explore our lineup to find the perfect hydraulic fittings for your industrial, commercial, or automotive applications in Malaysia.

What are SS316 tube fittings?

SS316 tube fittings are components used to connect and secure tubing in fluid handling systems. These fittings are made from SS316 stainless steel, offering excellent durability and resistance to corrosion, making them suitable for use in harsh environments and corrosive fluids.

What are the benefits of using SS316 tube fittings?

Using SS316 tube fittings offers several advantages, including exceptional corrosion resistance, high strength, and durability. They also provide leak-free connections, ensuring reliable performance in critical applications. Additionally, SS316 tube fittings are easy to install and maintain, reducing downtime and operational costs.

What applications are SS316 tube fittings suitable for?

SS316 tube fittings are widely used in industries such as oil and gas, petrochemical, chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing. They are suitable for applications involving corrosive fluids, high temperatures, and high-pressure conditions.

What are the primary advantages of utilizing non-metal pipes (e.g., PVC, HDPE) over traditional metal options in certain infrastructure and chemical transport projects?

Non-metal pipes offer distinct advantages in specific applications, particularly in infrastructure and chemical transport. Their inherent resistance to corrosion and rust makes them ideal for underground installations, wastewater systems, and chemical processing where metal pipes would degrade. They are also lightweight, simplifying transport and installation, and offer excellent flow characteristics due to smoother internal surfaces, reducing pumping costs. Furthermore, their non-conductive properties are beneficial in electrical safety-sensitive environments, providing a durable and cost-effective alternative to metal.

What critical factors should be considered when selecting the appropriate tube or pipe material for handling corrosive media or extreme temperatures?

When dealing with corrosive media or extreme temperatures, material selection is paramount. Key considerations include the chemical compatibility of the pipe material with the fluid being transported, the maximum and minimum operating temperatures, system pressure, and any potential external environmental stressors. Sunseal’s experts can guide you through options like specialized stainless steels for aggressive chemicals, or particular non-metal composites for non-reactive fluid transfer in a wide thermal range, ensuring the long-term integrity and safety of your system.